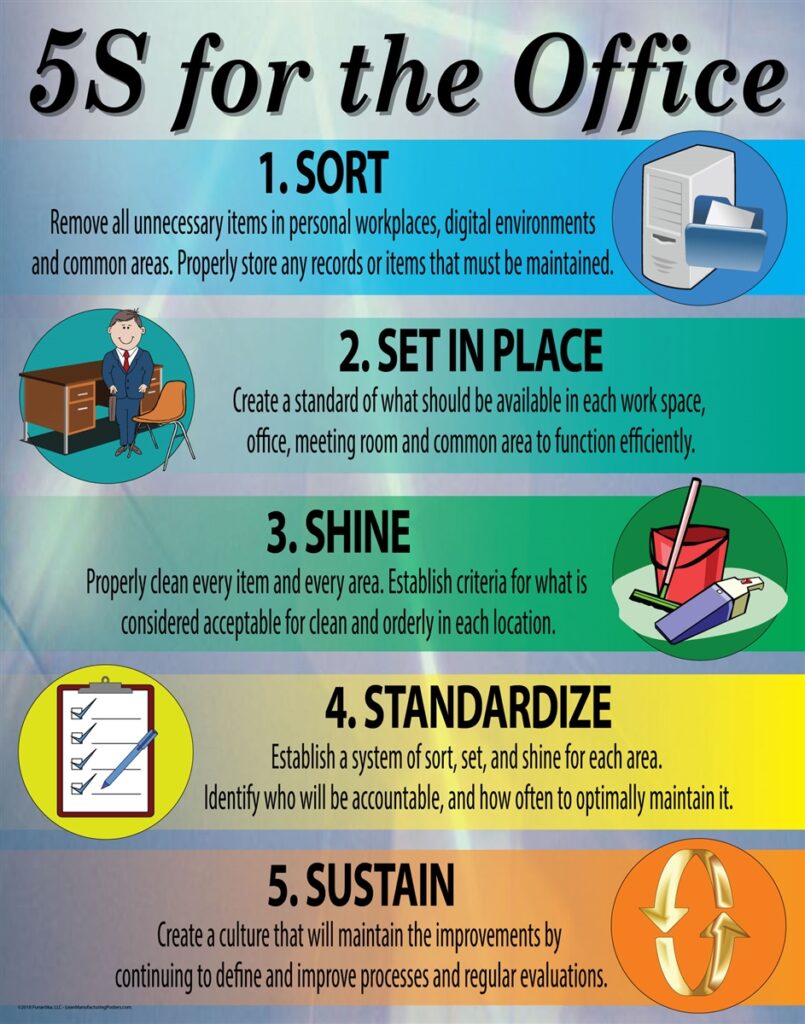

The application of the 5S system is for maintaining clean, safe, and efficient workplaces. The term originates from five Japanese words, each beginning with the letter “s” (Seiri=Sort, Seiton=Set in place, Seiso= Shine, Seiketsu=Standardize and Shisuke= Sustain), hence the name 5S. By lowering waste, increasing efficiency, and providing guidelines for staff members to follow, the technique ensures a constant level of quality in the work they produce.